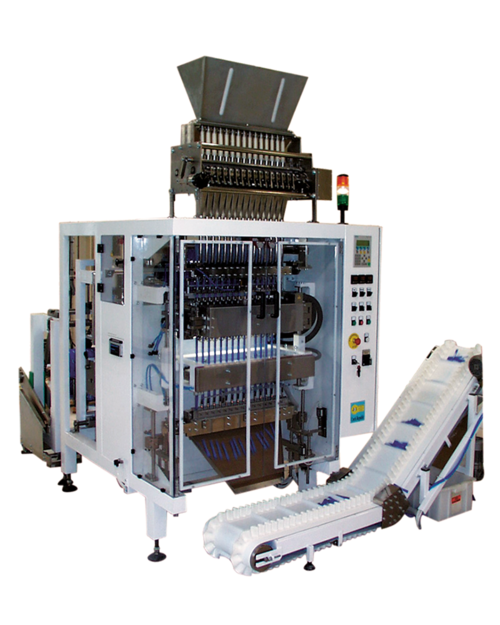

ABM EN series are high performance, reliable, fully automated, multilane vertical packaging machines with electro-pneumatic drive. It is suitable for loose, piece and liquid goods into stickpacks and flat bags sealed on three sides. Bags are made from an endless roll of heat sealable packing material. The foil is cut into individual narrow strips according to the number of tubes, passes through a forming part (without forming collar); all strips are sealed lengthwise and make sleeves. This sleeve is sealed by a cross jaw and a precise dose of packed goods is filled through a tube. The sleeve is pulled down for set length and pair of cross jaws seals it transversely.

Integrated blade cuts the bags off onto an exit conveyor that transports them for further handling (cartoning station, carton box, completion etc. All parts that come into contact with goods of food character are made of stainless steel AISI 304 (upon a special request also in AISI 316L). The packaging machine ABM EN is possible to combine with other optional accessories.

Advantages

highly efficient, reliable, variable, flexible, fully automated, multi-tube vertical packaging machine

varnished or stainless steel sturdy frame

electro-pneumatic drive

Siemens/Allen Bradley control systems provide fast and easy operation

possibility to store parameters for different products or packaging features

bag length settings mechanically in mm

easy conversion to other formats (more tubes, different bag width)

possibility to pack two different products of different weight on one packaging machine with two dosing devices without the need of packaging machine conversion

AISI 304 stainless steel finish (or AISI 316L upon customers request) meeting hygiene food contact requirements

safety focus – in-built door safety feature, central emergency stop button, main switch

sealing – heat (standard), impulse, ultrasound

cross seal raster types - linear grooving, diamond design

end of foil sensor, easy and quick fastening of new foil reel, automatic foil centering by sensors

simple control and operation

attractive and compact design

minimal maintenance requirements

Technical Data

| Maximal foil width | 1000 mm |

|---|---|

| Bag measurements | width 10-80 mm, lenght 40-250 mm |

| Number of tubes | 1-25 |

| Maximal output | 70 cycles (according to packed goods), up to 1750 bags/min. |

| Bag type | stickpack, flat, flat boiling, flat with euro hole |

| Control systems | SIEMENS, ALLEN BRADLEY |

| Drive | mechanical, electrical, pneumatic |

| Weight | 1050 kg (X), 1250 kg (XL), 1500 kg (XXL) |

| Cross seal | linear grooving, diamond design |

| Type of packed goods | loose, liquid, small pieces |